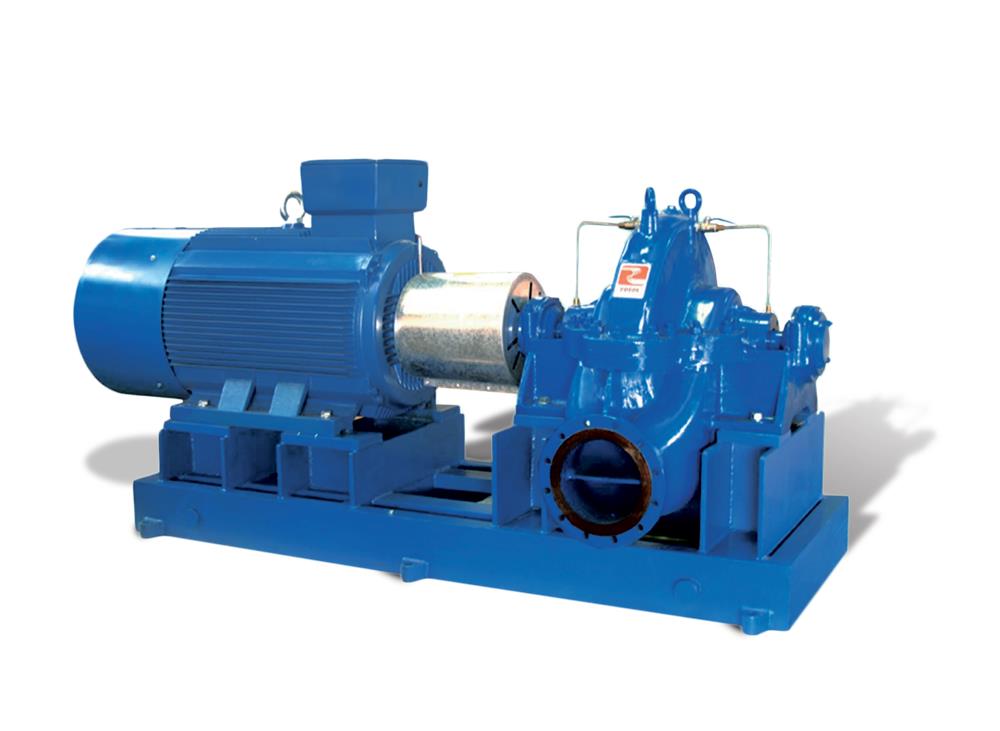

Gruppo Aturia Surface - Split-Case Pumps - PD & PDV series

FIELD APPLICATION

PD & PDV Pumps are used in civil, industrial and farming facilities, especially for.

- Municipal water supply

- Central heating

- Power plant

- Steel works

- Drainage pump station

- Petro-chemical industry

- Air conditioning

- Water treatment

- Fire-Fighting

The range includes 27 models with delivery nozzles from 125 to 350 mm, large sizes are available on request (delivery nozzles up to 450 mm).

CONSTRUCTION

PD & PDV pump casings, are split along the shaft axis and allow easy inspection and replacement of the rotating parts. The position of inlet and outlet nozzles (in the lower half case of PD horizontal pumps or in the rear half case of PDV vertical pumps) allows inspection and repair without removing the pump from its position. Impeller: Closed type the double suction grants stable operation, low energy cost, low noise, minimum vibrations and long life. Shaft: Protected by replaceable sleeves, it has no contact with the pumped fluid. Seals: Standard pumps are supplied with gland packing, and mechanical seals are available on request. Bearings: This range of pumps is almost free of hydraulic axial thrust; Thanks to the double suction symmetry and to the opposed impellers the bearings do not have to support axial loads. They are roller type, grease or oil lubricated. The rotating part is dynamically balanced and free of undue vibrations. Rotation speed: Pump performances refer to rotating speeds from 1450 to 970 rpm (at 50Hz) but these pumps can also run at different frequencies (60 Hz) or suit other requirements (subject to technical analysis). Coupling: Usually direct, with pump and motor on the same baseplate, coupled by means of a flexible joint, for horizontal assemblies; with motor stool lying on the pump in case of vertical assemblies. In the latter case the motor can also be mounted on a separate plate and coupled to the pump by means of universal joint. Standard – Testing – Tolerances: Standard nozzles comply with ISO 1092. On request, they can be machined according to DIN – ANSI and other standards. Tests and related tolerances as per ISO 9906 Gr.2.