Vertical Industrial Turbine Pumps

Applications

The pumps can be used in any industrial or agricultural application.

They can be used in:

- Steel works

- Chemical process plants

- Effluent Disposal

- Cooling Water Circulation

- Irrigation

- Water Works and Raw Water Supply

- Shaft Sinking and Dewatering

- Pipeline Booster and Transfer Service

- Condensate Extraction

Features

- Civil work is easier and cheaper.

- Installation is easier.

- There is no suction valve with consequent cost and pressure loss savings.

- Efficiencies are as good as any.

- NPSH probles are eliminated.

- Space is saved and by using weather proof motors, there is no necessity for a building to be erected.

- There is no danger of flooding the electrics.

- By adding stages, a very wide range of duties can be covered with standard parts, thus making for cheap and readily available spares.

- The pumps have generally a non-overloading KW characteristic, and a steep head quantity curve.

- There are no radical loads on the bearings or glands, so they last longer and maintenance is reduced.

- In dirty water, grit tends to fall vertically out of the wear areas and so does less damage.

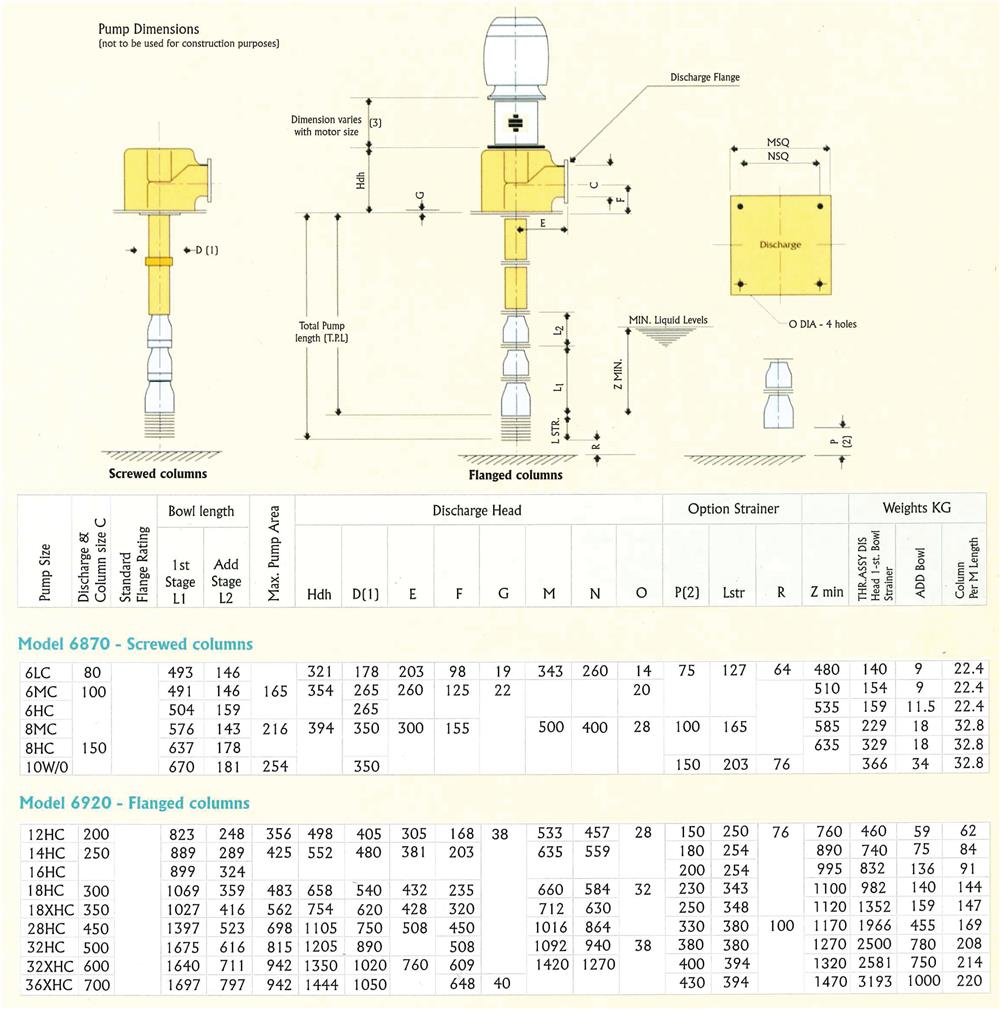

Specifications

The pump materials and assembly are selected from a number of standard variations to suit the particular application.

The casings are generally made in a high quality close-grained cast irion and have long radius water passages to give the best performance in terms of efficiency and life. Casings in bronze and stainless steel are also available.

The impllers are of mixed flow design and can be either open-vane or shrouded, depending on the size. The shrouded impellers have long suction eye rings, to give good life and performance. They are usually fitted to the shaft by means of a taper sleeve, using a key when the load requires it.

The shaft is of stainless steel, running in bearings chosen to suit the application. These include fluted cutless rubber, asbestos compounds and bronze. They can be product-lubricated or pressure-fed grease-lubricated.

The column pipe is either screwed or flanged steel suitably protected for the application. The bearing spiders are so high grade cast iron and the bearing brushes are as used in the pump. The line shafting can be product-lubricated or enclosed in a cover tube with oil, water or grease-lubricated.

The discharge head is either a rigid cast iron or fabricated steel bend with spigotted seats for the thrust bearing and drive motor stool. It contains the housing for the stuffing box.

Soft packed glands, mechanical seals, or a glandless arrangement can be offered.

Versatility of installation

The pumps are designed for any type of drive:

- Electric Motor

- Belt Drive

- Gear Drive

- Engine or Steam Turbine

They can be suspended in wet sumps, boreholes, rivers, steel tanks or dams; in dry pits with a suction pipe connected to the bellmouth or as a "pot" pump with various positions of the inlet and outlet branches.

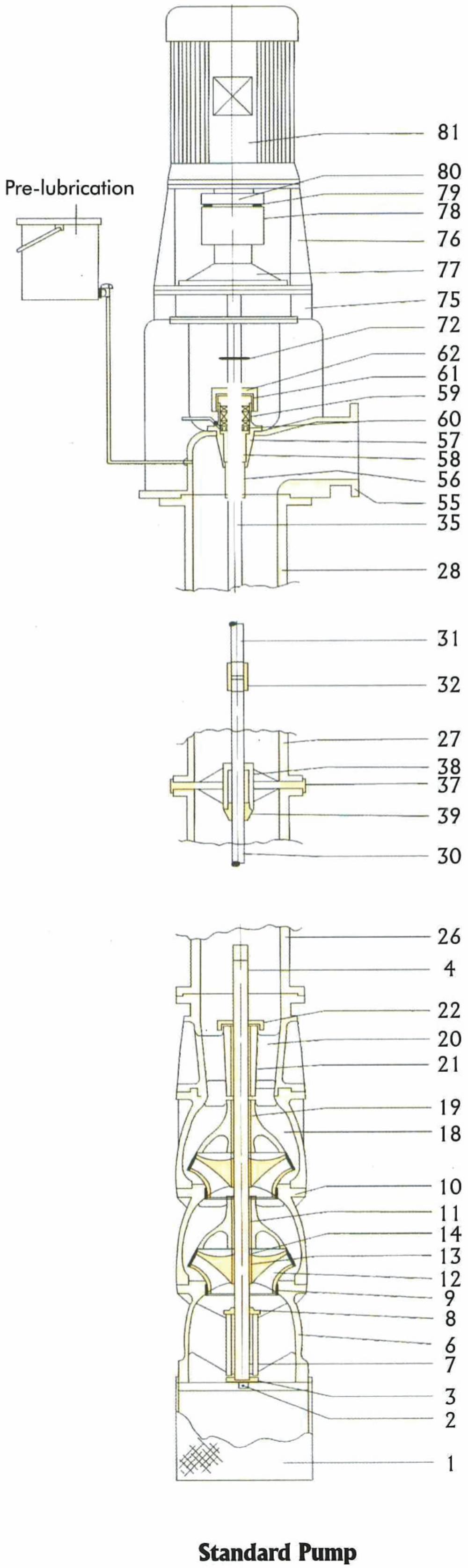

Sections and Parts

Discharge Head

81 Motor

80 Motor Half Coupling

79 Coupling Pins and Rubbers

78 Pump Half Coupling

77 Thrust Assembly

76 Motor Stool

75 Adaptor Stool

71 Grease or Water Line

70 Drip Feed Lubricator

69a Stuffing Box (relief type)

69 Cover Tube Stuffing Box

68 Cover Tube Top Cover Seal

67 Cover Tube Top Cover Bush

66 Cover Tube Top Cover

65 Tension Tube Cap

64 Tension Tube Locknut

63 Tension Tube Nut

62 Stuffling Box Cap

61 Gland

60 Lantern Rings

59 Gland Packing

58a S/B Bush (pressure system)

58 Stuffing Box Bush

57 Stuffing Box

56 Stuffing Tube

55 Discharge Head

Column Assembly

52 Cover tube circlip

51 Headshaft coupling key

50 Tension Tube

49 Covertube "O"-ring

48a Top C/tube ("O"-ring type)

48 Top C/Tube (for screwed col)

47a Interm C/tube ("O"-ring type)

47 Interm C/tube (for screwed column)

46a Bottom C/tube ("O"-ring type)

46 Bottom C/tube (for screwed column)

45 Convertible Connector Bearing

44 Column Spacer

43 Column Socket

42 Covertube Spider Bearing

41a Covertube Spider (screwed column)

41 Covertube Spider (flanged column)

40 Bearing Retainer Circlip

39 Bearing Retainer Cap

38 Bearing Retainer Bush

37b Brg Ret. (for screwed column)

37a Brg. Ret (for grease lub or water flush)

37 Bearing Retainer (flanged cols)

35 Head Shaft

34 Coupling Spacer

33 Ringer Feeder Locking Ring

32a Lineshaft Coupling (ring-feeder)

32 Lineshaft Coupling (screwed type)

31 Intermediate Lineshaft

30 Bottom Lineshaft

29 Connector Flange

28 Top Column

27 Intermediate Column

26 Bottom Column

Bowl Assembly

23a Top Connector Bearing ("O"-ring type)

23 Top Connector Bearing

22 Top Sand Slinger

21 Top-section Bush

20a Top-section (oil lub)

20 Top Section (water lub)

19 Top-Mid Section (bush)

18a Top-mid Section (screwed)

18 Top-mid Section (flanged)

17 Black Eye Ring Plate

16 Black Eye Ring

15 Pump Shaft Key

14 Impellar Taper Sleeve Lock Nutt

13 Impeller Taper Sleeve

12b Closed Impeller (back eye ring type)

12a Open Impeller

12 Closed Impeller

11 Middle Section Bush

10a Middle Section (screwed)

10 Middle Section (flanged)

9 Bottom Section Wear Ring

8 Bottom Sand Slinger

7 Bottom Section Bush

6a Bottom Section (screwed)

6 Bottom Section (flanged)

5 Sump

4 Pump Shaft

3 Upthrust Collar

2 Upthrust Collar Bolt

1a Borehole Strainer

1 Basket Strainer

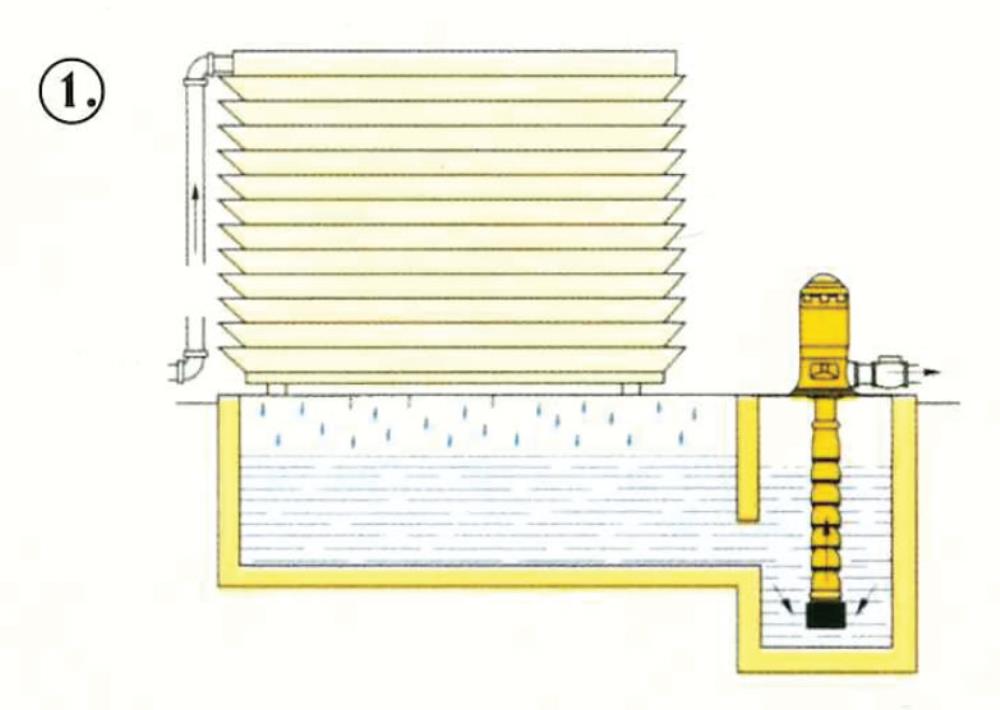

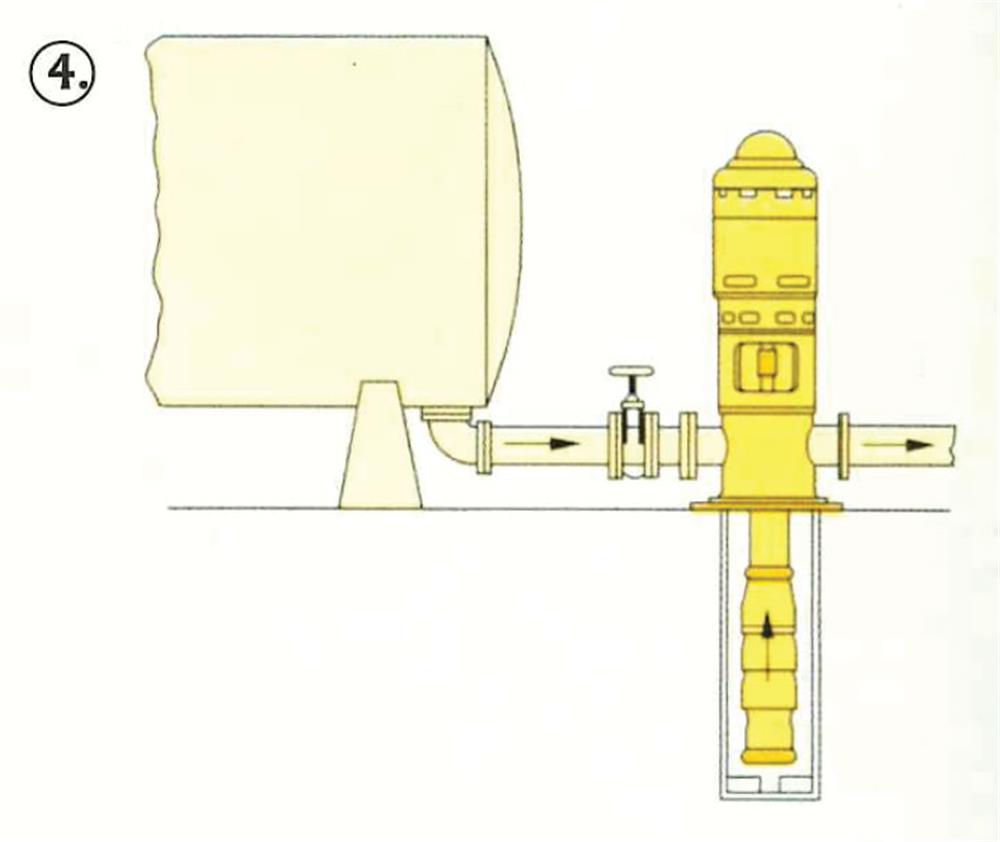

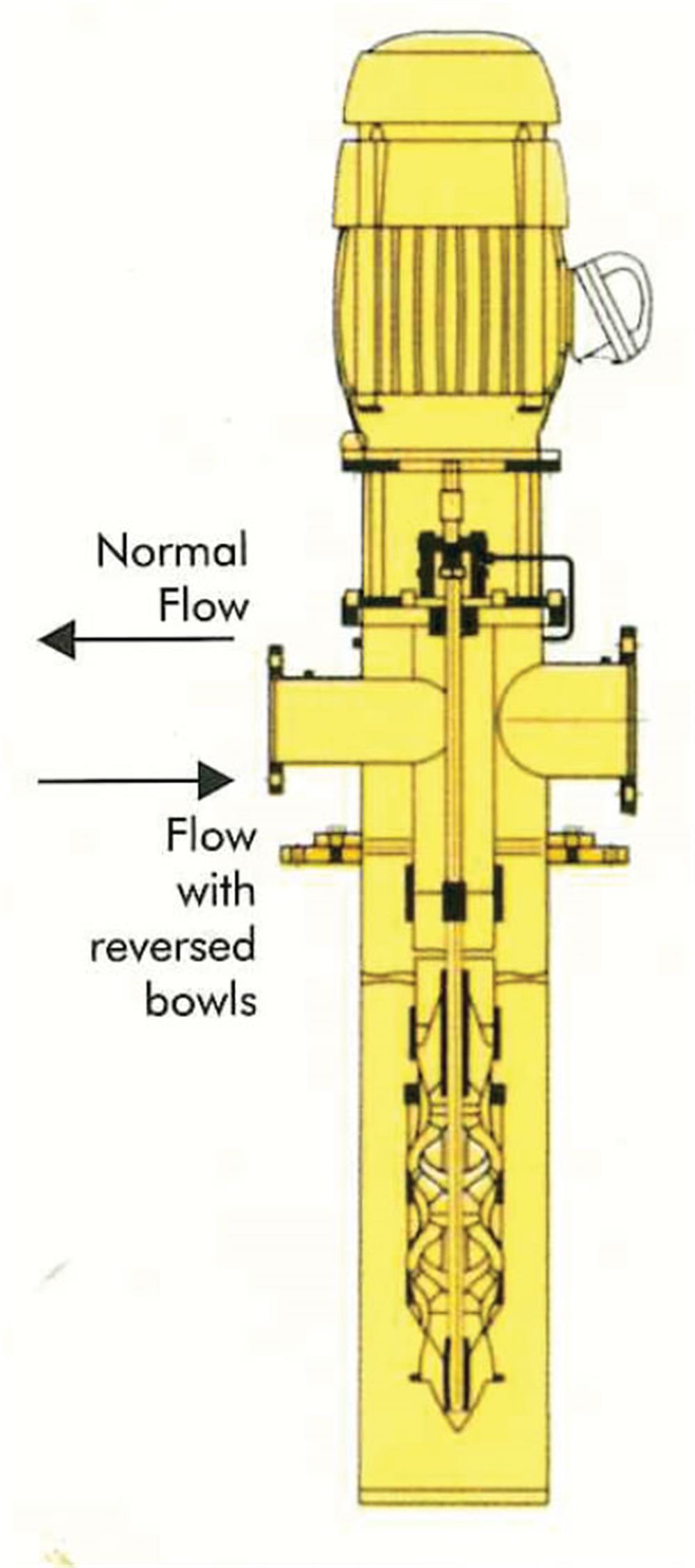

Typical Installations:

As a "Pot" Pump:

The "pot" pump is particularly useful for inline boosting. It requires no priming and to a limited extent is self priming. It conserves space and requires minimum civil work and operational maintenance.

By reversing the pump bowls, the flow direction is reversed and low pressure glands result, even in very high pressure boosting applications.

in other applications it can be made completel glandless.

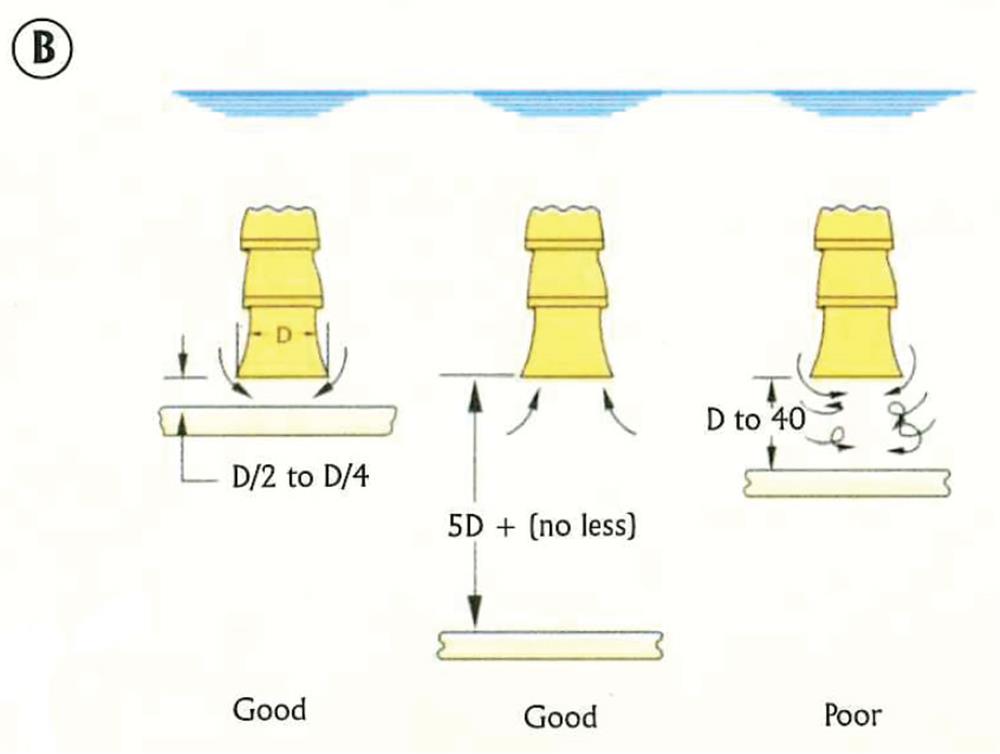

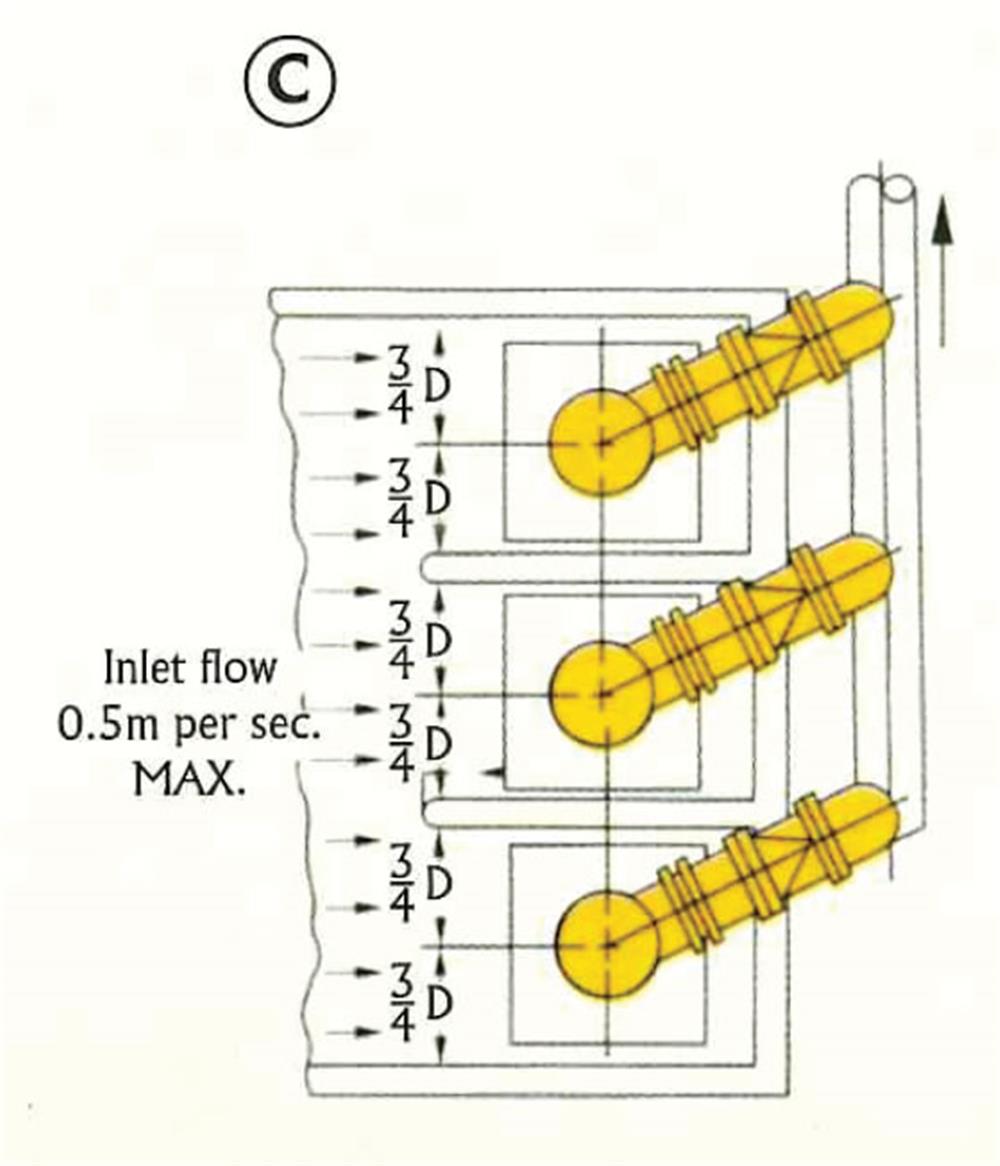

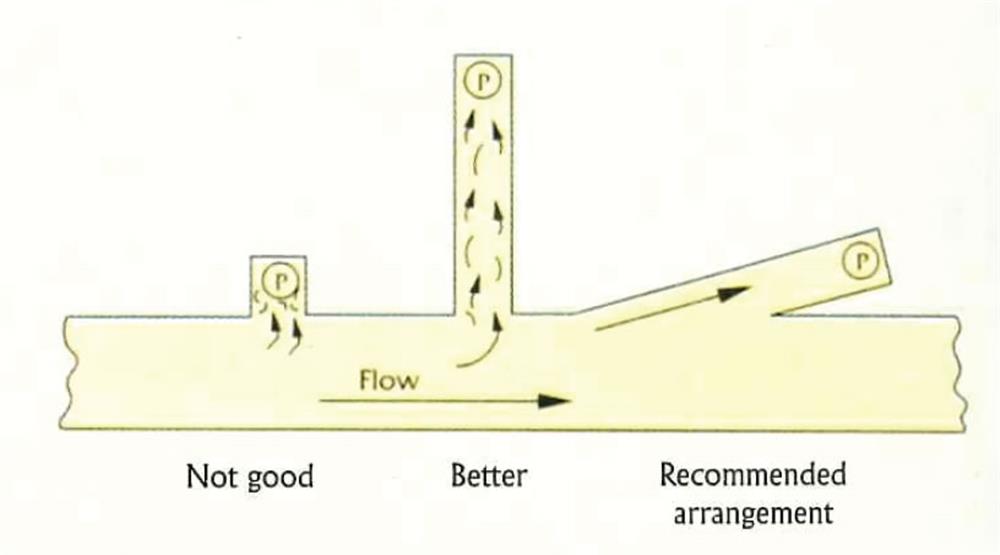

Sump Design

These sketches show some established criteria for proper sump design. These include submergence, clearance from the floor and walls, spacing between the units when more than one pump is involved, and flow distribution and velocities.